The stainless steel chain link fence uses this feature to implement the coating process. The uniformity of the powder fluidization state in the fluidized bed is the key to ensuring the uniformity of the coating film. The fluidized bed used in powder coating belongs to “vertical fluidization”. The fluidization number must be found through experiments. Generally, it can be coated. The suspension rate of the powder in the fluidized bed can reach 30-50 %. Chain link fence manufacturers are used to protect and support seawalls, hillsides, roads and bridges, reservoirs and other civil engineering. It is a good material for flood control and flood resistance. Can also be used for handicraft manufacturing.

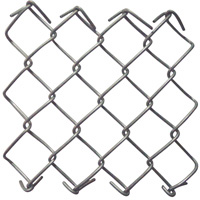

Warehouse, tool room refrigeration, protective reinforcement, ocean fishing fence and construction site fence, river course, slope fixed soil (rock), residential safety protection, etc. Chain link fence is made by crocheting metal wires of various materials by a chain link fence machine, which can be divided into two types: folding and shrinking handles and twisting and locking handles. The firmness of chain link fence refers to the tightness of the galvanized layer and steel. It is mainly required that galvanized components shall not peel off during the process of classification, transportation, storage and use. General inspection methods include hammering, bending, rolling, etc. The hammering method is to hit the test piece with a hammer to check the state of the coating film surface. Fix the test piece so that the height and level of the hammer support platform are equal, and the vertical position of the handle weight will not naturally drop. Hit 5 points in parallel every 4 mm to observe whether the film peels off.

Stainless steel chain link fence is a substitute for traditional paint and galvanized layer. It has the characteristics of corrosion resistance, rust prevention, moisture resistance, insulation, and aging resistance. Plastic spraying, also known as plastic coating, is mainly the process of melting and plasticizing the city film after the thermoplastic powder material is preheated, softened and cooled to form a fixed film.

It also has many forms. Because the net barrier itself is simple, generous, and can be shaped, it can meet the needs of the present invention. The whole society also has many different forms of performance. Net barrier is one of them. It has a unique design, has a good protective effect, and plays the corresponding protective effect well, and is deeply loved by people.

Post time: Nov-06-2020